Automation

The automation is the brain and the heart of every industrial equipment today.

Starting from a small machine to a big industry, automation is now controlling every step of production.

A process plant that is fully automated can gives a lot of benefit to the user and prevents most of the human mistakes.

Our solution does not stop at controlling the plant but

· It gives the complete acquisition of data from the field.

· It gives the opportunity to remote supervise the production.

· It gives the final customer to check their production report directly and have

their own traceability.

· It gives all the information required in a clever way.

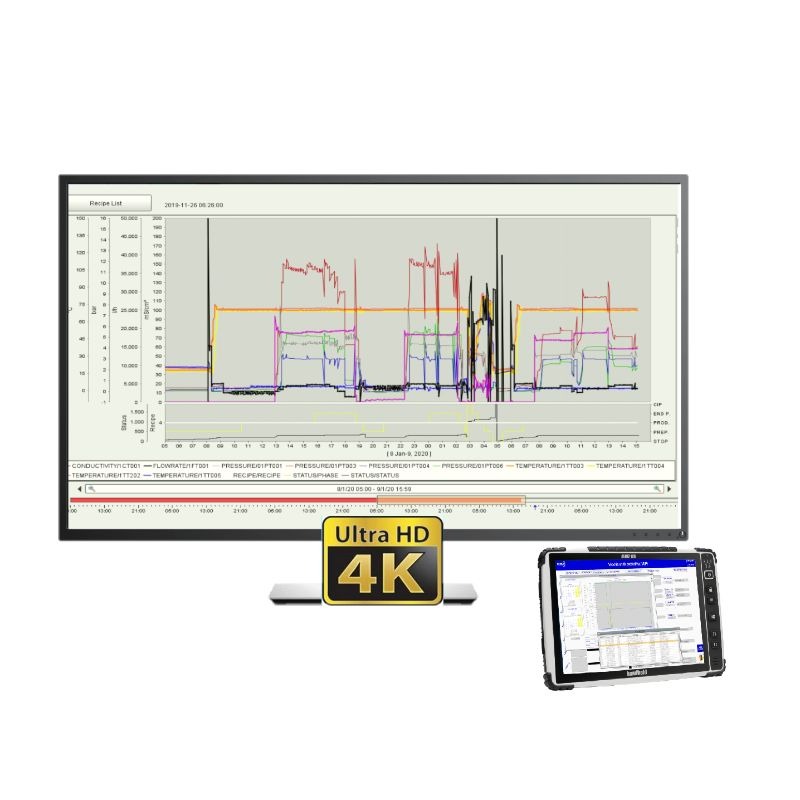

From the control room desktop PC, you will have access to all the plant areas and monitor the situation.

· All the parts of the plant will be accessible so, in every moment, the plant

situation will be under control.

· Production recipes and data recorded in database.

· All the probes recorded in historical groups recording up to one year data.

· Information logs about CIP and Pasteurization with production batches

information.

· Easy to use interface to select source and destination item on every line.

We allows also to control the full plant from tablet, So you can take the control room with you in every moment from your hand.

It will be possible to control every area of the system all the time by simply connect to wi-fi

As for the control room desktop PC, you will have access to all the plant from every area and see the situation. And decide action required , as example :

Go to the filtering room and select the destination tank, start & stop the filtering line or made some maintenance on it. Then move to the pasteurizer or UF and select the source and destination tank, call for a CIP and the start your production.

Additional option to use your mobile phone as a plant terminal to collect data (like QR code) or overview the factory situation.